TofuPilot x Enlightra

How Enlightra scaled photonic device testing from lab to production with TofuPilot's test infrastructure.

We're excited to share how Enlightra's engineering team has implemented TofuPilot to scale their photonic device testing from EPFL research lab to Y Combinator-backed production. Their journey demonstrates the critical role of test infrastructure in hardware development.

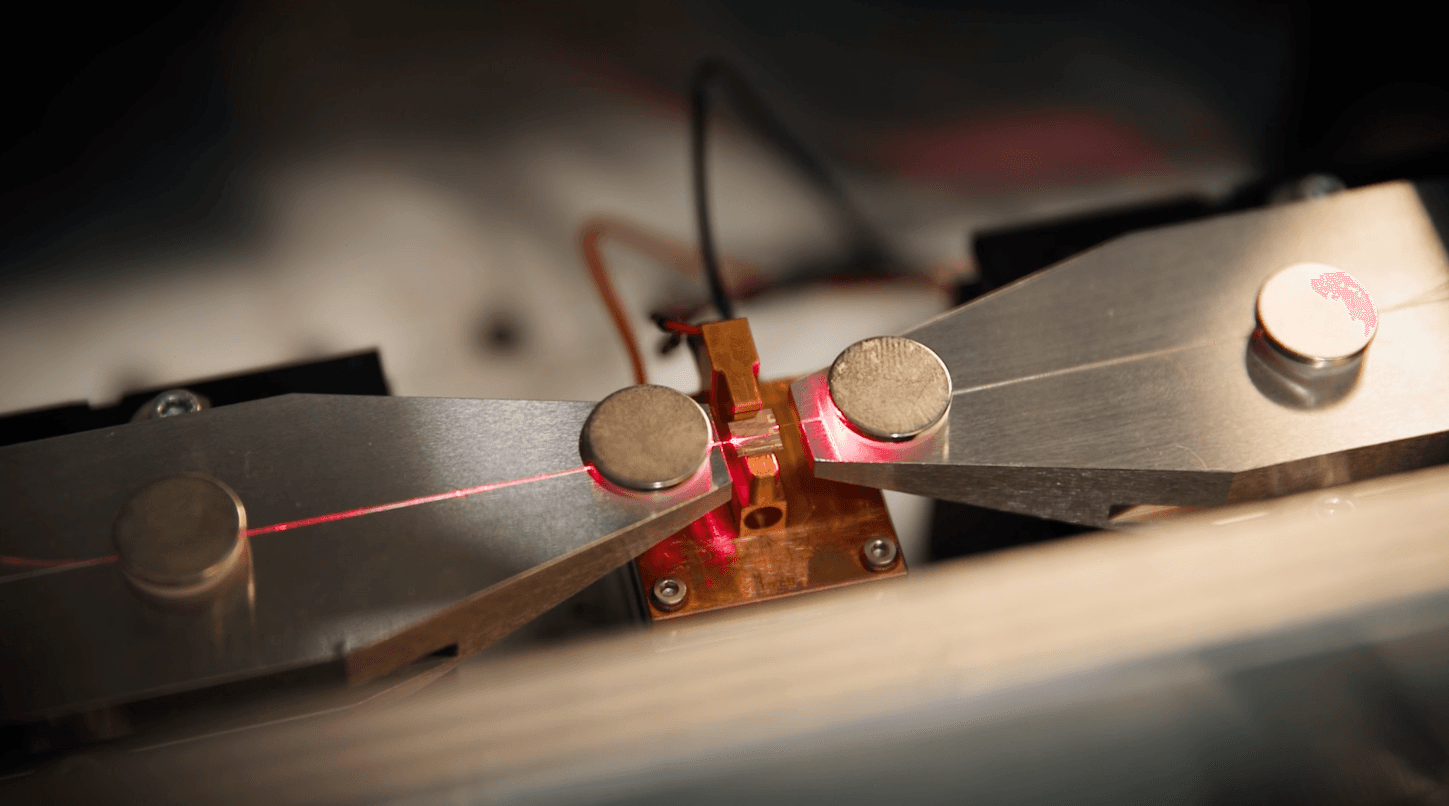

Enlightra is developing multicolor comb lasers for data center optical interconnects—technology that delivers 100x faster data transfer speeds and 10x energy reduction. As data centers approach consuming a fifth of global electricity by 2025, their photonic solutions address both performance and sustainability challenges in modern computing infrastructure.

Engineering Validation Complexity

Photonic devices demand rigorous validation across optical performance, thermal characteristics, and electrical interfaces. Each prototype contains dozens of precision components with tight tolerance requirements. The Enlightra team encountered typical scaling challenges that affect many hardware startups:

- Test data scattered across multiple measurement instruments and file formats

- Manual correlation between design specifications and measured performance

- Inconsistent protocols making results difficult to compare across prototype builds

- Limited traceability from test results back to component batches and assembly procedures

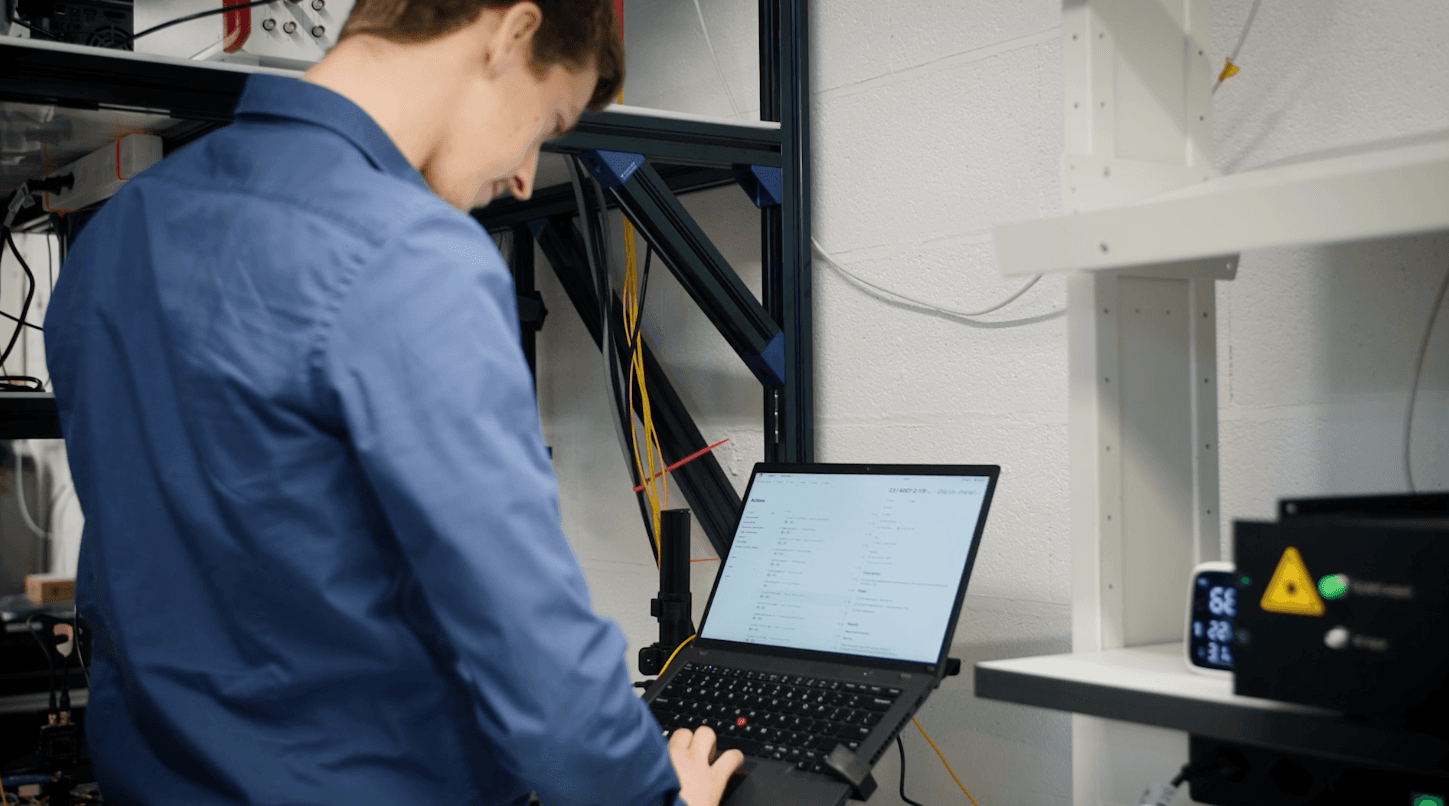

We needed a systematic approach to test data management that could scale with our development velocity. TofuPilot provided the infrastructure we needed to maintain engineering rigor while moving fast.

— Johana Bernasconi, Lead Engineer at Enlightra

Rapid Implementation

TofuPilot's asset tracking and test management system integrated seamlessly with Enlightra's existing workflow. Within two days, the team had established:

- Prototype Traceability: Each device build linked to component batch records, assembly procedures, and design revisions

- Standardized Test Protocols: Consistent validation sequences with automated parameter logging across different engineers

- Results Analysis: Direct correlation between measured performance and specifications with automated pass/fail determination

![]()

Production-Ready Test Infrastructure

As Enlightra's development pace accelerated, TofuPilot's defect tracking became essential for root cause analysis. When optical power measurements showed variation across device batches, the team could rapidly trace issues to specific manufacturing steps and component suppliers.

The visibility into our test data has transformed how we approach design iterations. We can now make data-driven decisions about design changes and identify optimization opportunities that weren't visible before.

— Johana Bernasconi, Lead Engineer at Enlightra

The platform now manages Enlightra's complete validation pipeline: from component characterization through packaged device testing to system-level integration validation. Test data flows automatically from measurement instruments into structured records, eliminating manual transcription and enabling statistical analysis across builds.

TofuPilot has become integral to Enlightra's development process—from cleanroom characterization to design review meetings. The platform provides the test infrastructure foundation that hardware teams need when transitioning from research prototypes to manufactured products.

Enlightra's success demonstrates how the right test management infrastructure can accelerate hardware development while maintaining the engineering rigor required for complex photonic systems.